Introduction:

The COVID-19 pandemic had me going stir-crazy indoors. It became clear that I’m not meant to be an indoor cat; I need to be outside, doing something. During a conversation with my former boss about his Mini Cooper, I inquired if he’d ever consider selling it. About a year after his retirement, he called me up and said, “Come get the car.” Initially hesitant, I declined, but he sold it to me anyway—perhaps that’s the mark of a seasoned sales leader. I got the car for a steal, so no complaints there.

Getting Started:

To tackle the project, I enlisted a couple of buddies—one to assist with the car inspection and another to lend me a trailer for transportation. The Mini Cooper had its fair share of issues, with a fallen tree and a long period of inactivity. Unsure about the challenges ahead, but fueled by boredom, I secured and inspected the car, then towed it home.

The Challenge:

Undertaking a project of this scale was a first for me. While I’ve been hands-on with my vehicles for years, restoring a Mini Cooper posed a unique set of challenges. Drawing confidence from past automotive projects, including replacing a clutch in a recently sold Jeep, I set a goal: to complete the refresh and have the Mini Cooper back on the road within a year.

Getting Down to Basics: Addressing Brake Issues in My R53 Racing Project

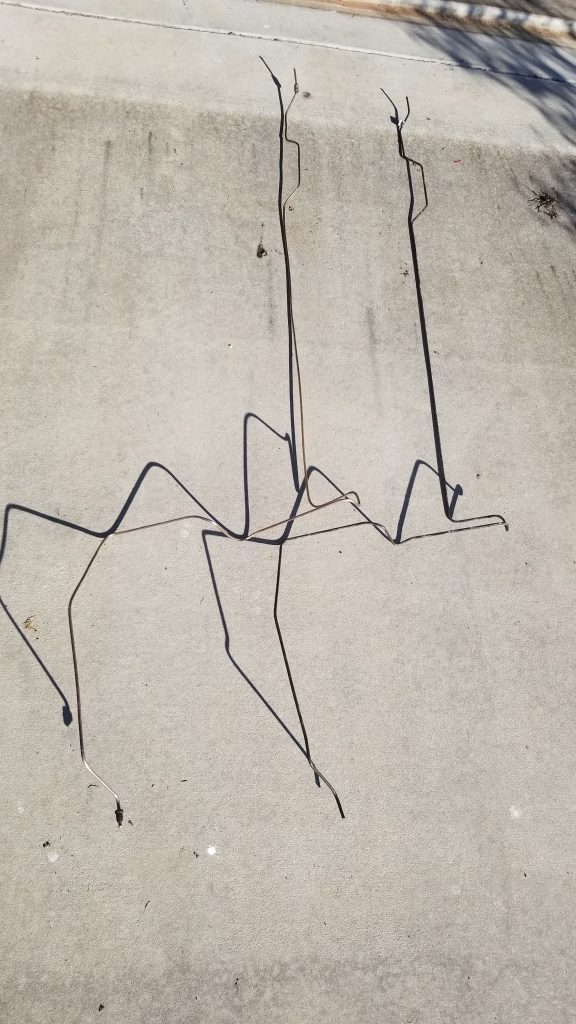

After bringing the Mini Cooper R53 home, the first order of business was taking inventory, revealing a laundry list of tasks ahead. Among the pressing concerns were the basics: ensuring the car could both go and stop. Unfortunately, the brake lines were rusted through and ruptured, presenting a major obstacle.

The decision to prioritize fixing the brakes before tackling other issues was a no-brainer. After all, I wanted to be absolutely certain I could stop before focusing on getting the car to go!

My limited experience with brake work in the past involved merely replacing pads and rotors. However, the extent of the damage to the Mini Cooper R53’s brake lines required a more comprehensive approach. Opting for pre-fabricated brake lines through BMW proved to be an expensive and time-consuming solution. Not only did they come with a hefty price tag, but they also required additional fabrication to fit correctly.

Undeterred, I took matters into my own hands. Instead of shelling out for pre-made lines, I decided to purchase the raw materials and the necessary tools to fabricate the brake lines myself. This not only proved to be a cost-effective solution but also provided me with the satisfaction of hands-on fabrication.

Refurbishing Brakes and Elevating the Car Safely

As I delved into sorting out the brake lines, it became evident that the brakes themselves required attention. Instead of opting for new ones, I made the decision to refurbish the original brakes if possible. To enhance braking, I decided on cross-drilled and slotted rotors promptly placing an order for them.

However, a new challenge emerged – how to safely elevate the car for these repairs. I had no desire to crawl under a car precariously perched on jack stands, especially after witnessing a set fail. Safety became paramount.

To address this concern, I invested in a set of quick jacks, envisioning their utility across all my vehicles. This not only promised a safer working environment but also offered time and cost savings for future oil changes, brake jobs, and tire rotations.

With the safety measures in place, the brakes took a trip to a local shop, High Tech Powder Coating in Boonsboro MD, for sandblasting. The results were nothing short of fantastic. Armed with freshly blasted brakes, I took the DIY route, opting for a coat of high-temperature specialized brake paint. Red was chosen to add a splash of color in a sea of gray and black.